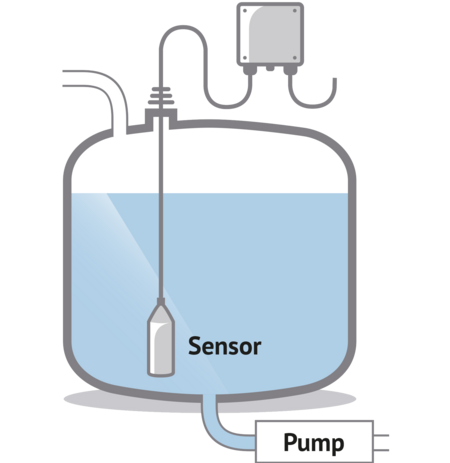

Level monitoring of pressurized vessels

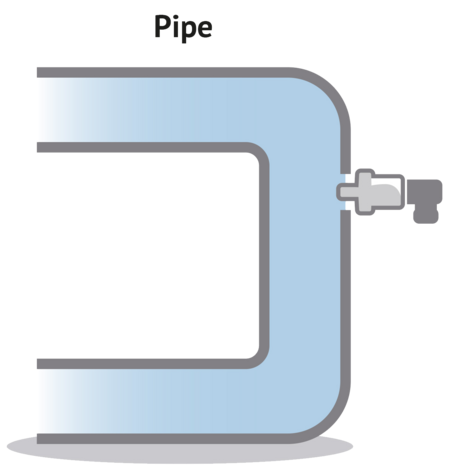

On the "high side" of the transmitter, the vessel pressure plus the hydrostatic pressure

resulting from the filling level is measured. On the "low side", only the vessel pressure

is measured. The difference results in the filling level, which is output as an electronic signal.

Your advantages

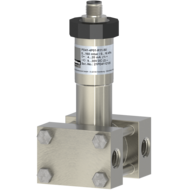

- Overload capability of up to 250 bar even with the smallest measuring range

- Due to a single measuring cell, the computation of 2 signals is not required and therefore the measurement is very accurate

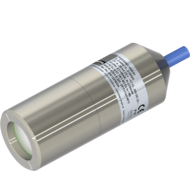

- Available in fully welded version, therefore also suitable for aggressive media